An important application area of stainless steel woven mesh, is petrochemical industry, this kind of stainless steel woven mesh is high quality standard item, that is very critical to grantee raw material alloy content, mesh micron accuracy and broken wire or double wire elimination.

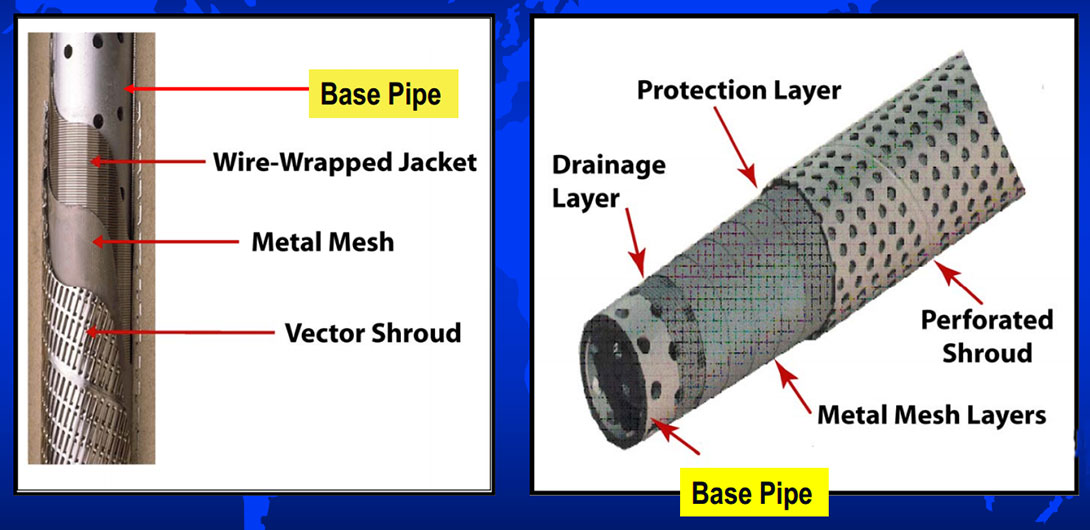

Screen are an integral part of most downhole sand control strategies. Based on pores, there are Pre-Packed Screen, Shrouded Metal Mesh Screen and Expandable Screen. Sand Control Screens are mechanical filtration or retention devices to:

Provide sand retention of the gravel pack and or formatio sand.

Allow passage of fluids during well clean up,production or any stimulation activities, products covered: Wire Wrap Screens, Pre-Pack Screens and Metal Mesh Screens.

Ure shall be performed if customer has this customized requirement.

Stainless steel mesh developed in 1980s.

Consists of base pipe,layered filtration jacket and outer shroud.

Less demage occurs during installation.

Corrosion resistence of stainless steel mesh.

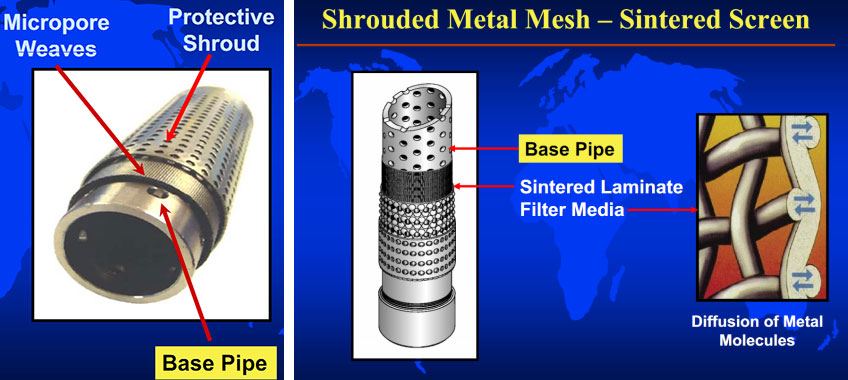

Special welding technique eliminates costly sintering; Double –layer media and uniform pores improves performance.

Normal specification for Dutch weave

| Whitehouse sample# | Weaving Type | Target | Actural |

| 1 | Plain Dutch | 125 | 142 |

| 2 | 138 | ||

| 3 | 140 | ||

| 4 | 138 |

| Whitehouse sample# | Weaving Type | Target | Actural |

| 1 | Plain Dutch | 250 | 251 |

| 2 | 250 | ||

| 3 | 244 | ||

| 4 | 251 |

| Whitehouse sample# | Weaving Type | Target | Actural |

| 1 | Plain Dutch | 175 | 160 |

| 2 | 162 | ||

| 3 | 160 | ||

| 4 | 160 |

| Whitehouse sample# | Weaving Type | Target | Actural |

| 1 | Twill Dutch | 200 | 197 |

| 2 | 199 | ||

| 3 | 197 | ||

| 4 | 196 |

Sintered stainless steel mesh introduced in 1990s

Consists of base pipe,multi-layer sintered metal mesh jacket and outer shroud.

Similar demage and corrosion resistance to non-sintered.

High pore size accuracy,even 100um diameter sand can be controlled.

| Filter Mesh Weave Pattern | Plain Square | Plain Dutch | ||||||||||

| Support Screen Weave Pattern | Plain Square | Plain Square | ||||||||||

| Norminal Filter rating,micron | 140 | 175 | 200 | 250 | 300 | 400 | 50 | 80 | 95 | 125 | 175 | 250 |

| Number of layers | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 3 | 3 | 3 | 3 | 3 |

| Min.pore,micron | 100 | 125 | 150 | 180 | 240 | 240 | 40 | 50 | 65 | 90 | 150 | 200 |

| Max.pore,micron | 175 | 225 | 250 | 320 | 380 | 400 | 70 | 100 | 120 | 150 | 250 | 300 |

| Min.Air Permeability,Darcy | 600 | 600 | 600 | 700 | 700 | 700 | 320 | 325 | 400 | 400 | 450 | 400 |

| Min.Porosity,% | 58 | 58 | 58 | 58 | 57 | 57 | 58 | 60 | 58 | 53 | 54.8 | 52 |

Till now ,we manufactured and supplied mesh roll as majority items for this sand screen ,Square Plain and single layer Dutch weave is well developed.

For mesh panels and mesh with annealing condition ,we also could make it as customer individual requirement.

| Ultra-thin Net | |||||

| Mesh count | Aperature Size | Wire Dia. | Opening Area(%) | ||

| inch | mm | Inch | mm | ||

| 16×16 | 0.0535 | 1.36 | 0.009 | 0.229 | 73.3 |

| 18×18 | 0.0466 | 1.18 | 0.009 | 0.229 | 70.2 |

| 24×24 | 0.0342 | 0.869 | 0.0075 | 0.191 | 67.2 |

| 28×28 | 0.0282 | 0.716 | 0.0075 | 0.191 | 62.4 |

| 30×30 | 0.0268 | 0.681 | 0.0065 | 0.165 | 64.8 |

| 36×36 | 0.0213 | 0.541 | 0.0065 | 0.165 | 58.7 |

| 40×40 | 0.0185 | 0.47 | 0.0065 | 0.165 | 54.8 |

| 50×50 | 0.0145 | 0.368 | 0.0055 | 0.127 | 52.6 |

| 60×60 | 0.0122 | 0.31 | 0.0045 | 0.114 | 53.3 |

| 70×70 | 0.0106 | 0.269 | 0.0037 | 0.094 | 54.9 |

| 76×76 | 0.0095 | 0.241 | 0.0037 | 0.094 | 51.7 |

| 80×80 | 0.0088 | 0.224 | 0.0037 | 0.094 | 49.6 |

| 90×90 | 0.0076 | 0.193 | 0.0035 | 0.089 | 47.8 |

| 94×94 | 0.0071 | 0.18 | 0.0035 | 0.089 | 45 |

| 105×105 | 0.0065 | 0.165 | 0.003 | 0.076 | 46.9 |

| 120×120 | 0.0058 | 0.147 | 0.0025 | 0.064 | 47.3 |

| 165×165 | 0.0042 | 0.107 | 0.0019 | 0.048 | 47.1 |

| 200×200 | 0.0034 | 0.0864 | 0.0016 | 0.0406 | 46.2 |

| 230×230 | 0.0029 | 0.0737 | 0.0014 | 0.0356 | 46 |

| Plain Weave | |||||

| Mesh count | Wire Dia | Width of Opening | Open area | ||

| Inches | mm | Inches | mm | % | |

| 1X1 | 0.157 | 4 | 0.84 | 21.4 | 71 |

| 4X4 | 0.063 | 1.6 | 0.187 | 4.75 | 56 |

| 8X8 | 0.043 | 1.1 | 0.08 | 2.08 | 42 |

| 10X10 | 0.039 | 1 | 0.06 | 1.54 | 36 |

| 12X12 | 0.023 | 0.584 | 0.06 | 1.52 | 51.8 |

| 14X14 | 0.023 | 0.584 | 0.048 | 1.22 | 45.2 |

| 16X16 | 0.018 | 0.457 | 0.0445 | 1.13 | 50.7 |

| 18X18 | 0.017 | 0.432 | 0.0386 | 0.98 | 48.3 |

| 20X20 | 0.016 | 0.406 | 0.034 | 0.86 | 46.2 |

| 24X24 | 0.014 | 0.356 | 0.0277 | 0.7 | 44.2 |

| 30X30 | 0.012 | 0.305 | 0.0213 | 0.54 | 40.8 |

| 35X35 | 0.011 | 0.279 | 0.0176 | 0.45 | 37.9 |

| 40X40 | 0.01 | 0.254 | 0.015 | 0.38 | 36 |

| 50X50 | 0.008 | 0.203 | 0.012 | 0.31 | 36 |

| 60X60 | 0.0075 | 0.19 | 0.0092 | 0.23 | 30.5 |

| 70X70 | 0.0065 | 0.165 | 0.0078 | 0.2 | 29.8 |

| 80X80 | 0.0055 | 0.14 | 0.007 | 0.18 | 31.4 |

| 100X100 | 0.0043 | 0.11 | 0.0055 | 0.14 | 32.15 |

| 120X120 | 0.0031 | 0.08 | 0.0046 | 0.132 | 38.77 |

| 150X150 | 0.026 | 0.06 | 0.0041 | 0.1041 | 37.4 |

| 180X180 | 0.002 | 0.05 | 0.0036 | 0.091 | 41.65 |

| 200X200 | 0.0021 | 0.05 | 0.0029 | 0.0737 | 35.49 |

| 250X250 | 0.0012 | 0.03 | 0.0028 | 0.0716 | 49.4 |

| 300X300 | 0.0012 | 0.03 | 0.00215 | 0.05467 | 41.67 |

| 325X325 | 0.0012 | 0.03 | 0.0019 | 0.0482 | 38.09 |

| 400X400 | 0.001 | 0.025 | 0.00152 | 0.0385 | 36.72 |

| Twill Weave | |||||

| Mesh count | Wire Dia | Width of Opening | Open area | ||

| Inches | mm | Inches | mm | % | |

| 20 | 0.0236 | 0.6 | 0.02638 | 0.670 | 44.89 |

| 30 | 0.0177 | 0.45 | 0.01562 | 0.397 | 15.73 |

| 40 | 0.0118 | 0.3 | 0.01319 | 0.335 | 11.22 |

| 50 | 0.0098 | 0.25 | 0.01016 | 0.258 | 6.66 |

| 60 | 0.0094 | 0.24 | 0.00722 | 0.183 | 3.36 |

| 80 | 0.0071 | 0.18 | 0.00541 | 0.138 | 1.89 |

| 100 | 0.0059 | 0.15 | 0.00409 | 0.104 | 1.08 |

| 120 | 0.0047 | 0.12 | 0.00361 | 0.092 | 0.84 |

| 150 | 0.0031 | 0.08 | 0.00352 | 0.089 | 0.80 |

| 250 | 0.0016 | 0.04 | 0.00243 | 0.062 | 0.38 |

| 270 | 0.0016 | 0.04 | 0.00213 | 0.054 | 0.29 |

| 300 | 0.0016 | 0.04 | 0.00176 | 0.045 | 0.20 |

| 325 | 0.0014 | 0.035 | 0.00170 | 0.043 | 0.19 |

| 400 | 0.0012 | 0.03 | 0.00132 | 0.034 | 0.11 |

| 500 | 0.0010 | 0.025 | 0.00102 | 0.026 | 0.07 |

| 635 | 0.0008 | 0.02 | 0.00079 | 0.020 | 0.04 |

| Dutch Weave | |||||

| Warp Count | Weft Count | Warp Wire | Weft Wire | Norminal (micron) | Absolute Range |

| 8 | 85 | 0.43 | 0.32 | 250 | 225-260 |

| 12 | 64 | 0.58 | 0.4 | 300 | 260-280 |

| 12 | 72 | 0.4 | 0.38 | 300 | 260-280 |

| 16 | 80 | 0.43 | 0.34 | 200 | 210-230 |

| 24 | 110 | 0.355 | 0.25 | 120 | 112-125 |

| 30 | 150 | 0.23 | 0.18 | 90 | 90-105 |

| 40 | 200 | 0.18 | 0.14 | 70 | 70-75 |

| 50 | 250 | 0.14 | 0.114 | 60 | 56-63 |

| 80 | 400 | 0.125 | 0.071 | 40 | 40-45 |

Downhole sand screens are important for the production of oil, gas and water, which are usually located deep underground. Large drilling rigs are used to drill holes below the surface to collect oil or gas. The sand screen is then inserted into the hole to allow natural oil and gas to enter while preventing the sand from flowing out, except for very fine particles. The sand screen is like a separator of gas, oil and sand. Once large sand enters the hole, it can reduce production and even make the drilling equipment inoperable.

The selection of sand screen mesh is usually based on the size of the hole and the sand particles. If the hole is too large, it will cause a large amount of sand to enter the screen mesh and clogging will occur in the near future. However, if the holes are too fine, production will be affected. Sand screens are selected to balance production and sand collection.

Milesen Metal Net Products was established in 2006 and has assembled a professional R&D team. We will analyze the formation sand and recommend the right sand screen for your specific well application.

Sand control screens can affect production and equipment performance. Therefore, you should consider them carefully before planning. If you have any questions, feel free to email us with suggestions and inquiries.