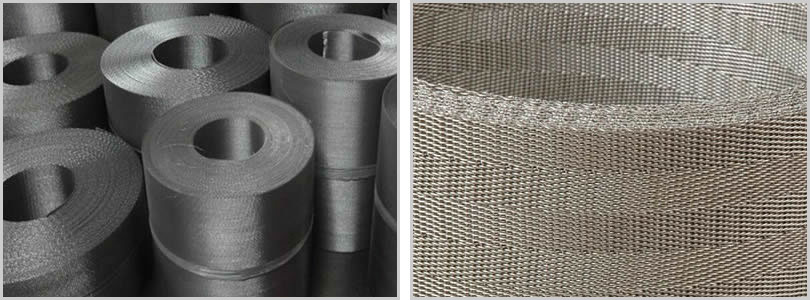

Stainless steel wire mesh ,galvanized wire mesh and plain steel wire mesh ,the major application is plastic and rubber filtration. Extruder screen is an important part in the melt filtration and extrusion process.

Manual Screen Changer:

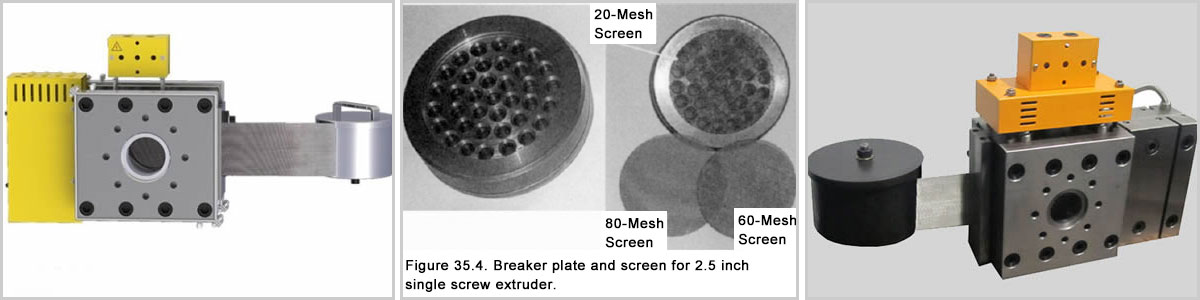

Manual screen changers are available with two breaker plates mounted in a metal plate close to one another.With a long handle ,one breaker plate and screen pack is moved out of the melt stream with the second one is inserted into the melt flow path.This system is inexpensie and works very well in a discontinuous operation.

Extruder screen is an important part in the melt filtration and extrusion process. It can efficiently keep out the foreign particles in mixing in finally plastic and rubber extrusion process and provide a extrusion.

Our extruder screens are made of steel, stainless steel, galvanized wire and brass wire mesh. It can be single or multi-layers wire mesh. Multi-layers extruder screens are fastened by spot welding or with aluminum frame. Besides, its shapes can be various including circle, disc, oval, rectangular, cones and other special shape. Our extruder screens with different filtration rate meet different filter applications.there are many designs and sizes of wire mesh, it is common to use a 20/60/120/60/20 mesh screen with square plain weave and with mini 100um with square twill weave and Dutch weave from 8um to 80um.

Automatic screen changers are used in continuous processes where contamination can glog normal screen packs in a relatively short time compared to the production run time. The screen changer or filtering system chosen depends on the process, the throughput rate, the run length, the contamination, and the extruder size.

Filtration systems available include:

1. Braker plate with screen pack.

2. Hydraulic slide plate, each fast or slow movement.

3. Double bolt.

4. Ribbon-type screen or continuous breaker plates.

5. Rotary disk filter.

Ribbon –type screen changers use long or continuous screen material that moves through the polymer flow channel. The screen is pulled by a hydraulic clamp or pushed through the melt by the melt presure. As the melt pressure increases, it pushes the screen forward to provide clean screen for filtering; This is a semicontinuous process, with the melt pressure acting as the driving force to provide fresh screen. The screen is a continuous ribbon that is sealed to prevent polymer leakage by cooling the ribbon where it enters and exits to form a polymer seal. This systems provide continuous filtration with minimal moving parts and a simplified system.

We call this Ribbon –type screen as RDTW belt, this belt will be directly put into the machinery, Normally the width of the belt is 55mm-200mm and 2 or 3 different meshes is in a compound mode, with high rate and low rate.

For this kinds of mesh, typical requirements on quality are as follows:

1. Mesh defects such as broken wire, pin holes not allowed

2. Mesh width tolerence: can be minus, plus is not accepted

3. Warp wire tensile strength is not fixed. Normal warp tensile strength is 600-800N/mm² and high tensile strength requires to 1200-1400N/mm²

| Normal Specifications of RDTW Belt | ||

| Weave Type | Mesh specification | Nominal Filter Rate Micron |

| RDTW | 72/15 | 300 |

| RDTW | 132/14 | 220 |

| RDTW | 132/18 | 175 |

| RDTW | 152/24 | 120 |

| RDTW | 250/40 | 90 |

| RDTW | 338/37 | 55 |

| RDPW | 180/120 | 75 |

| RDPW | 400/125 | 40 |

| RDPW | 600/125 | 28 |