| Availability: | |

|---|---|

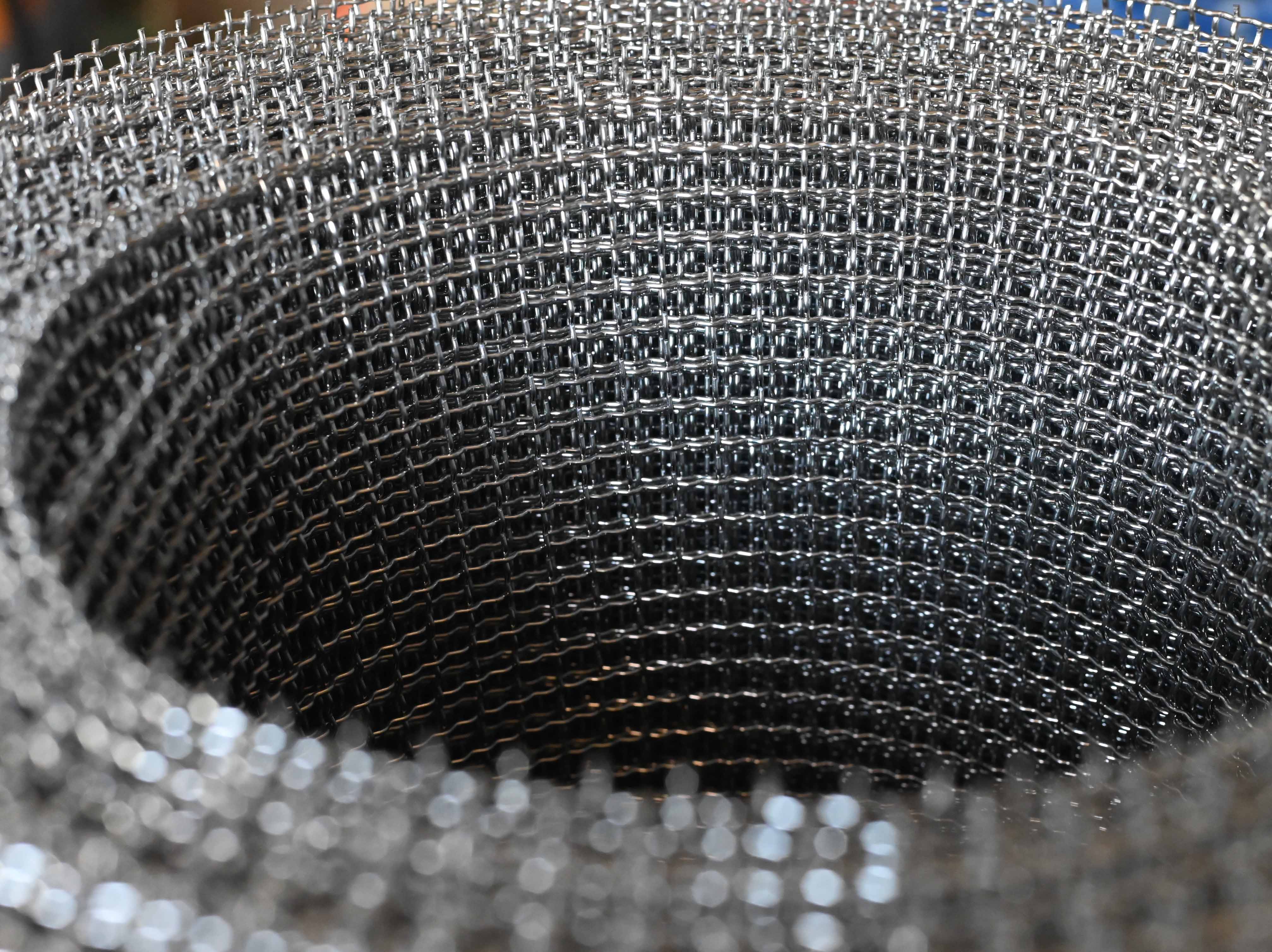

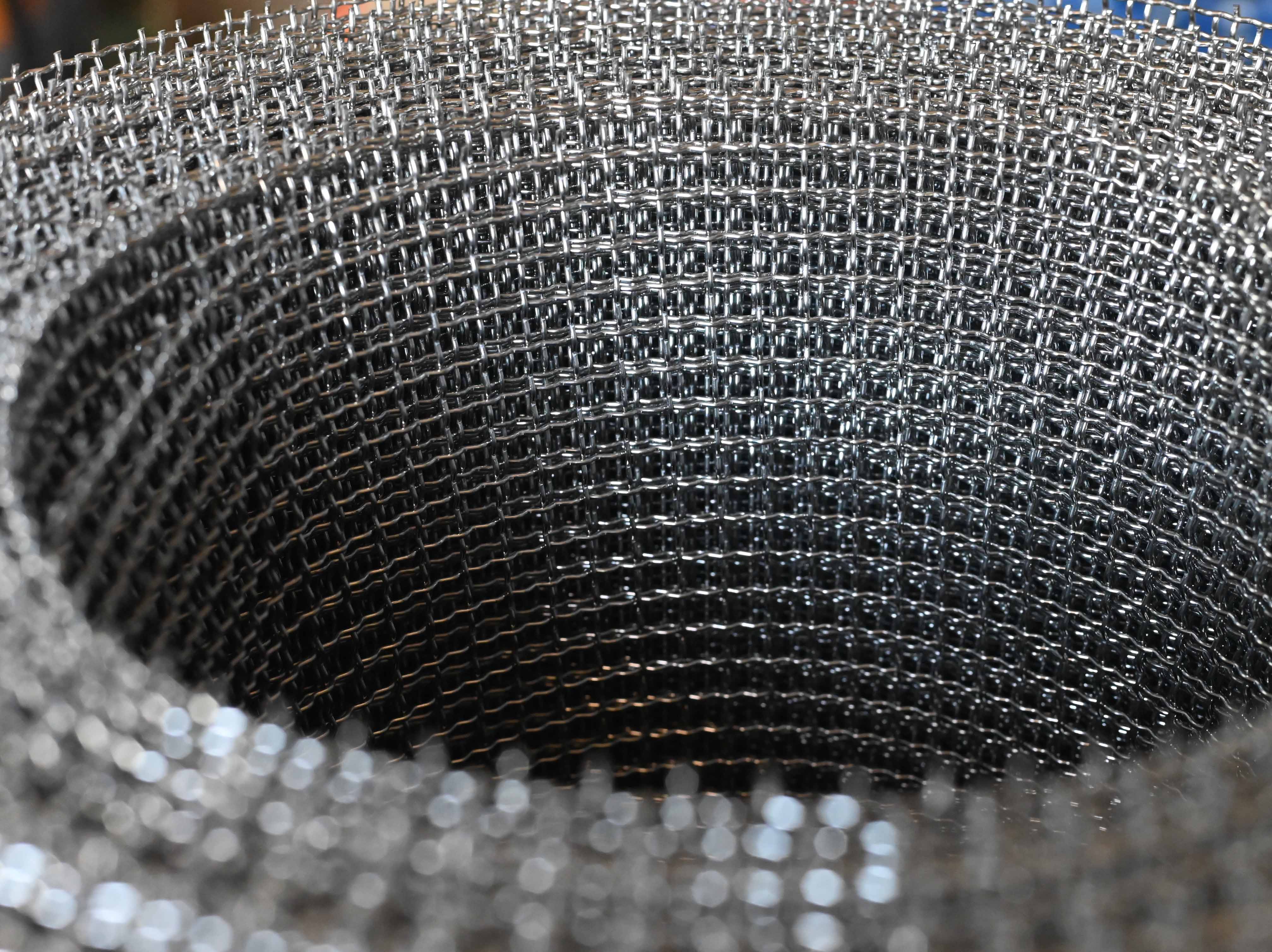

We are Stainless Steel Crimped Mesh manufacturers&Suppliers,We look forward to establishing a long-term relationship with you.

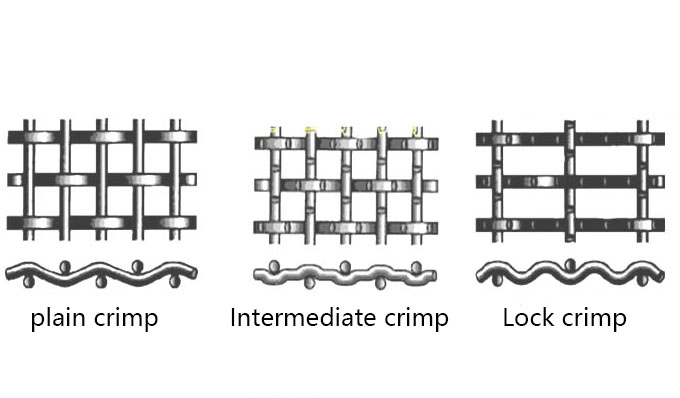

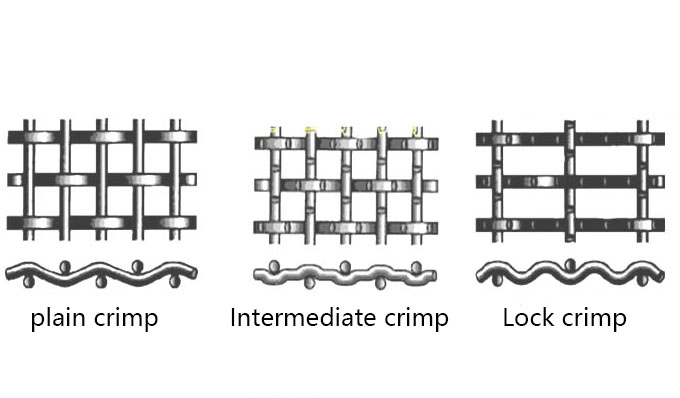

Milesen supplied the crimped mesh with mainly three types: Plain Crimped,Intercrimp and the Lock Crimp.

"plain crimp" has emerged into everyday industry jargon, and while it is not an officially defined term by the ASTM 2016-06 standard for industrial woven wire cloth (defined below), it does provide clarity into this topic. "Plain crimp" is a simple, almost-natural crimp in which each intersecting wire interlocks with the next adjacent wire. Oftentimes, "plain weave" and "plain crimp" are used to convey similar concepts. Our own rule of thumb is that most, but not all, plain weave is plain crimp, but all plain crimp is plain weave. Indeed, the pictures below both show "Plain Weave" (one wire over/one wire under) :

"Intermediate crimp" or simply "intercrimp" describes the popular crimp type that is used when woven wire mesh is manufactured. With intercrimp, both the warp wires (the wires that run the length of the roll) and shute wires (wires that run the width of the roll) are pre-crimped before the mesh is woven. Intermediate crimp is usually employed in coarser meshes to obtain large openings with relatively light wires. The hallmark of an intermediate crimp is the corrugations in the wire, which adds to the stability of the mesh. As a rule, the larger the opening size, the more number of crimps.

"Lock crimp" is a crimp type that is commonly employed when woven wire mesh is manufactured. Similar to intermediate crimp, "lock crimp" is also comprised of pre-crimped wires. The distinguishing feature of lock crimp is the bump or knuckle that forms over each intersecting set of wires. These knuckles lock the mesh in place and create an extremely rigid product. And finally, the wires on a lock crimp are straight between intersections, while the wires with the intermediate crimp are corrugated.

| Specifications | ||

| Mesh/Inch | Wire Diameter(mm) | Aperture(mm) |

| 21 | 2 | 1 |

| 18 | 4.05 | 1 |

| 20 | 0.5 | 0.61 |

| 18 | 0.61 | 0.8 |

| 16 | 0.55 | 0.1 |

| 14 | 0.55 | 0.12 |

| 12 | 0.71 | 0.14 |

| 2.3 | 1 | 0.18 |

| 1.2 | 4.8 | 2 |

| 1 | 4.8 | 2 |

| 0.7 | 4.8 | 3 |

| 5.08 | 2 | 0.3 |

| 2.1 | 2 | 1 |

| 3.6 | 2 | 1.5 |

We are Stainless Steel Crimped Mesh manufacturers&Suppliers,We look forward to establishing a long-term relationship with you.

Milesen supplied the crimped mesh with mainly three types: Plain Crimped,Intercrimp and the Lock Crimp.

"plain crimp" has emerged into everyday industry jargon, and while it is not an officially defined term by the ASTM 2016-06 standard for industrial woven wire cloth (defined below), it does provide clarity into this topic. "Plain crimp" is a simple, almost-natural crimp in which each intersecting wire interlocks with the next adjacent wire. Oftentimes, "plain weave" and "plain crimp" are used to convey similar concepts. Our own rule of thumb is that most, but not all, plain weave is plain crimp, but all plain crimp is plain weave. Indeed, the pictures below both show "Plain Weave" (one wire over/one wire under) :

"Intermediate crimp" or simply "intercrimp" describes the popular crimp type that is used when woven wire mesh is manufactured. With intercrimp, both the warp wires (the wires that run the length of the roll) and shute wires (wires that run the width of the roll) are pre-crimped before the mesh is woven. Intermediate crimp is usually employed in coarser meshes to obtain large openings with relatively light wires. The hallmark of an intermediate crimp is the corrugations in the wire, which adds to the stability of the mesh. As a rule, the larger the opening size, the more number of crimps.

"Lock crimp" is a crimp type that is commonly employed when woven wire mesh is manufactured. Similar to intermediate crimp, "lock crimp" is also comprised of pre-crimped wires. The distinguishing feature of lock crimp is the bump or knuckle that forms over each intersecting set of wires. These knuckles lock the mesh in place and create an extremely rigid product. And finally, the wires on a lock crimp are straight between intersections, while the wires with the intermediate crimp are corrugated.

| Specifications | ||

| Mesh/Inch | Wire Diameter(mm) | Aperture(mm) |

| 21 | 2 | 1 |

| 18 | 4.05 | 1 |

| 20 | 0.5 | 0.61 |

| 18 | 0.61 | 0.8 |

| 16 | 0.55 | 0.1 |

| 14 | 0.55 | 0.12 |

| 12 | 0.71 | 0.14 |

| 2.3 | 1 | 0.18 |

| 1.2 | 4.8 | 2 |

| 1 | 4.8 | 2 |

| 0.7 | 4.8 | 3 |

| 5.08 | 2 | 0.3 |

| 2.1 | 2 | 1 |

| 3.6 | 2 | 1.5 |